VANCOUVER, British Columbia – Graphite One Inc. (“Graphite One”, “G1” or the “Company”) announced that it has identified the presence of Rare Earth Elements (“REEs”) in its Graphite Creek deposit, north of Nome, Alaska. Geochemical analyses completed by Activation Laboratories Ltd (“ActLabs”) found rare earths in drillcore samples of garnet-bearing ore rock within the anticipated pit outlined in G1’s Feasibility Study (“FS”), completed in February 2025. Already recognized by the United States Geological Survey as the largest known natural graphite deposit in the U.S.[1], G1’s FS resource estimate tripled previous projections. The FS pit and its anticipated 20-year mine life comprises just 12% of the 15.3 km (9.5 mile) long graphite- and garnet-bearing mineralized zone.

“The presence of two Defense Production Act Title III materials – graphite and REEs – in a single deposit further underscores Graphite Creek’s position as a truly generational deposit,” said Anthony Huston, President of Graphite One. “Given the robust economics of our planned complete graphite materials supply chain, the presence of Rare Earths at Graphite Creek suggests that recovery as a by-product to our graphite production will maximize the value.”

Rare Earth Elements are vital to 21st Century technology, with neodymium, praseodymium, dysprosium, terbium and samarium forming essential building blocks of powerful permanent magnets used in wind turbines, electric vehicles and advanced defense systems such as precision-guided munitions and radar. REEs further enable high-performance fiber optics, lasers, catalysts, and phosphors in displays and lighting. Their distinct magnetic, optical and catalytic properties make them indispensable across military applications and commercial electronics, renewable energy, and telecommunications – underscoring their strategic importance to U.S industry and national security.

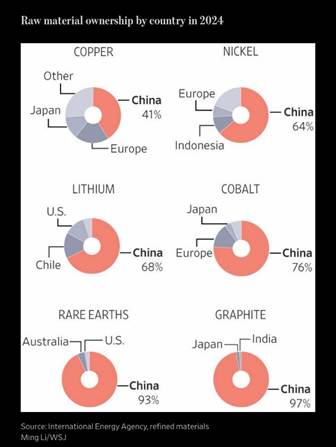

China, the world’s largest producer of the full range of REEs, imposed export limits on the magnet REEs in February 2024 and tightened graphite exports in December 2024, highlighting the importance of the development of G1’s Graphite Creek Mine. A recent UBS Evidence Labs report indicates that dependence on China for a select group of Critical Minerals is most severe for graphite and REE.

Test work on 21 representative samples from quartz-biotite-garnet-sillimanite schist units throughout the FS pit indicate elevated levels of the Heavy Rare Earths (“HREEs”) and the presence of the five principle REE magnet elements – Neodymium, Praseodymium as well as HREEs Dysprosium and Terbium – in addition to Samarium, which is used in Samarium Cobalt (“SmCo”) permanent magnets. Aside from the Lanthanide HREEs, the Graphite Creek garnet-bearing ore rock contains Scandium and elevated Yttrium. “Garnets are known for their ability to uptake Heavy Rare Earths and Yttrium into their mineral structure,” said Dr. Kirsten Fristad, G1 Chief Geologist.

Building on the initial bulk rock analyses, additional test work is being completed at the University of Alaska Fairbanks Advanced Instrumentation Laboratory and Activation Laboratories Ltd to quantify the REE inventory within the host mineralogy. G1 is in discussions with a Department of Energy National Lab to develop extraction methods and separation pathways for the individual REEs in the Graphite Creek ore.

The Graphite Creek Feasibility Study was completed more than 12 months ahead of schedule with the support from the Department of War (then DoD) via a $37.5 million Defense Production Act Title III grant. In September 2025, G1 received a non-binding Letter of Interest from the EXIM Bank for $570 million in funding for the Graphite Creek Mine, the second EXIM Letter of Interest G1 has received, after a $325 million letter for the development of the Company’s Ohio advanced graphite materials facility. G1 is in ongoing discussions with senior officials at all relevant federal departments and agencies on the Company’s complete supply chain strategy for advanced graphite products. “We will now be adding updates on our Rare Earth by-product potential,” said Mr. Huston.

Graphite One’s Domestic Supply Chain Strategy

With the United States currently 100% import-dependent for natural graphite, Graphite One is developing a complete U.S.-based, advanced graphite supply chain solution anchored by the Graphite Creek deposit, recognized by the US Geological Survey as the largest graphite deposit in the U.S. “and among the largest in the world.” The Graphite One Project supply chain strategy involves transporting material to the lower 48 via the Port of Nome to an advanced graphite material and battery anode material manufacturing plant located in Warren, Ohio. The plan also includes a recycling facility to reclaim graphite and the other battery materials, to be co-located at the Ohio site, the third link in Graphite One’s circular economy strategy.

Qualified Person

Mr. Rob Retherford, P. Geo, with Alaska Earth Sciences, Inc. provided oversite to the 2022-2024 drilling, sampling, and QA/QC programs. Mr. Retherford is an independent Qualified Person as defined under NI 43‐101 and has reviewed and approved the technical content of this release.